Super Efficient Vacuum Glazing

Using vacuum glazing to reduce energy consumption is a great way to improve the comfort of homes and offices. Vacuum glazing is a process in which a sealant is applied to the glass or window. The sealant acts as a barrier to the air and reduces heat transfer between the glass and the interior environment. It is an environmentally friendly alternative to standard windows and is very cost-effective, too.

Fabrication Of Energy-efficient Vacuum Glazing

Using vacuum glass, the energy efficiency of windows is maximised. This is achieved by creating a vacuum between the two rigidly held panes of glass. This is a critical technique in building energy efficient buildings. As well as maximising the thermal efficiency of windows, the technique also minimises heat transfer between the insulating panes of glass. Therefore, a vacuum glazing unit can reduce heating energy consumption.

The fabrication of energy-efficient vacuum glazing is an important development in the field of energy-efficient buildings. However, the costs of this technology are significantly higher than those of double-glazed windows. In addition to the cost of materials, the overall fabrication costs are higher. The University of Sydney is carrying out a research project on the development of vacuum glazing. The project is designed to test the durability of the glazing structure and the internal vacuum. It has created 500 vacuum glazings, which have been subjected to various stress tests. The project has also studied the effect of different coatings on the thermal performance of the glazing.

Design Strategies For Vacuum Glazing

Various design strategies for super efficient vacuum glazing have been proposed over the years. Some of them include the use of a drop-down insulating screen. Other methods include a more elaborate use of lighting to mitigate energy loss. There are also many ways to improve the efficiency of current designs. New window technologies will require huge improvements to energy consumption. Some of these innovations will involve changing the frame material, adding surface films, and using less conducting materials.

In addition to the usual window framing, a good window assembly must have an air pocket between the glass panes. This pocket should be big enough to accommodate a 0.1 Pa pressure. There is no simple way to calculate the exact size of the air pocket. However, if the gap between the panes is about a millimeter, then the total area should be about tenth of a cubic meter. The best way to increase this amount is to create a more substantial and well insulated box. In the case of a clad box, a brick thermal mass can be used to provide the added heat required.

Performance Verification Of Samples Using New Cost-Effective Sealing Materials

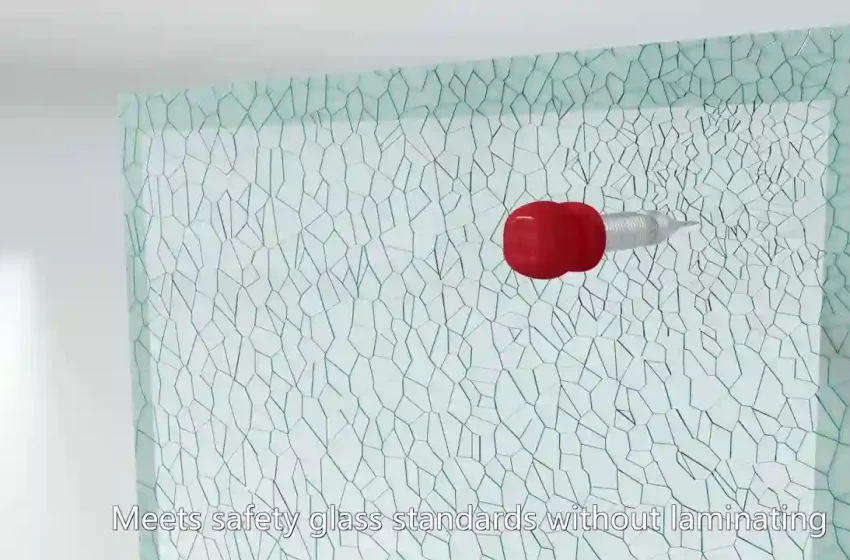

Compared to conventional glazing, vacuum insulated glass (VIG) panels have superior thermal performance over a period of twenty-five years. These panels are also thinner and lighter than conventional insulating technologies. Moreover, their heat transfer coefficients can be as low as 0.4 W/m2 K.

Next decade super glass for new construction has many advantages, it is also susceptible to degradation over time. This is because of the presence of support pillars that are exposed to sunlight. In the long term, this exposure can lead to degradation of the pillars. In addition, the spacing between the support pillars should be large enough to avoid damaging the glass panes. In order to optimize the thermal performance of the vacuum insulation, a study is underway. A number of techniques are being employed, including fractal methods and genetic algorithms. This study aims to create a suitable numerical model for future studies. It also investigates the effects of certain geometrical parameters on the dynamic response of VIG plates.

Thermal Insulating Performance Of Vacuum Glazing

Various researchers have investigated the thermal insulating performance of vacuum glazing. The results indicate that it can be used to achieve lower U-values for exterior walls. However, the cost is higher. These systems are not yet fully commercialized. Nevertheless, they have shown some interest in the technology.

Traditional vacuum glazing involves two sheets of glass separated by a vacuum space. This reduces the radiant heat transfer between the sheets. The inner core is made of a low thermal conductivity material. A thin layer of super-insulating material is also applied to one of the sheets. These three layers are then sealed together with glue. The sealing process is a complex process.

Final Thought

Whether you are looking to replace your existing windows or build a new building, vacuum glazing can have a big impact. These innovative windows eliminate heat loss caused by convection and provide excellent thermal insulation and sound blocking properties. In addition, these windows have a lower U-value than double-glazed units, which means they are more energy efficient. They are also lead-free and recyclable. They can be included in almost any traditional glazing system.